Safety Data Sheets

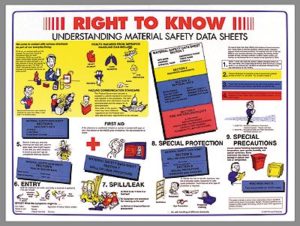

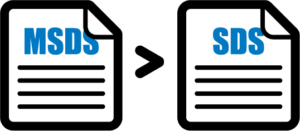

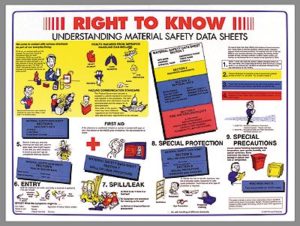

The Hazard Communication Standard (HCS) (29 CFR 1910.1200(g)), revised in 2012, requires that the chemical manufacturer, distributor, or importer provide Safety Data Sheets (SDSs) (formerly MSDSs or Material Safety Data Sheets) for each hazardous chemical to downstream users to communicate information on these hazards. The information contained in the SDS is largely the same as the MSDS, except now the SDSs are required to be presented in a consistent user-friendly, 16-section format. This brief provides guidance to help workers who handle hazardous chemicals to become familiar with the format and understand the contents of the SDSs.

The SDS includes information such as the properties of each chemical; the physical, health, and environmental health hazards; protective measures; and safety precautions for handling, storing, and transporting the chemical. The information contained in the SDS must be in English (although it may be in other languages as well). In addition, OSHA requires that SDS preparers provide specific minimum information as detailed in Appendix D of 29 CFR 1910.1200. The SDS preparers may also include additional information in various section(s).

Sections 1 through 8 contain general information about the chemical, identification, hazards, composition, safe handling practices, and emergency control measures (e.g., fire fighting). This information should be helpful to those that need to get the information quickly. Sections 9 through 11 and 16 contain other technical and scientific information, such as physical and chemical properties, stability and reactivity information, toxicological information, exposure control information, and other information including the date of preparation or last revision. The SDS must also state that no applicable information was found when the preparer does not find relevant information for any required element.

The SDS must also contain Sections 12 through 15, to be consistent with the UN Globally Harmonized System of Classification and Labeling of Chemicals (GHS), but OSHA will not enforce the content of these sections because they concern matters handled by other agencies.

A description of all 16 sections of the SDS, along with their contents, is presented below:

Section 1: Identification

This section identifies the chemical on the SDS as well as the recommended uses. It also provides the essential contact information of the supplier. The required information consists of:

- Product identifier used on the label and any other common names or synonyms by which the substance is known.

- Name, address, phone number of the manufacturer, importer, or other responsible party, and emergency phone number.

- Recommended use of the chemical (e.g., a brief description of what it actually does, such as flame retardant) and any restrictions on use (including recommendations given by the supplier).

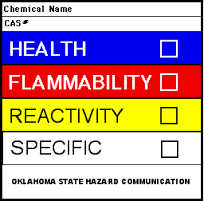

Section 2: Hazard(s) Identification

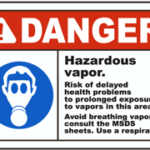

This section identifies the hazards of the chemical presented on the SDS and the appropriate warning information associated with those hazards. The required information consists of:

- The hazard classification of the chemical (e.g., flammable liquid, category).

- Signal word.

- Hazard statement(s).

- Pictograms (the pictograms or hazard symbols may be presented as graphical reproductions of the symbols in black and white or be a description of the name of the symbol (e.g., skull and crossbones, flame).

- Precautionary statement(s).

- Description of any hazards not otherwise classified.

- For a mixture that contains an ingredient(s) with unknown toxicity, a statement describing how much (percentage) of the mixture consists of ingredient(s) with unknown acute toxicity. Please note that this is a total percentage of the mixture and not tied to the individual ingredient(s).

Section 3: Composition/Information on Ingredients

This section identifies the ingredient(s) contained in the product indicated on the SDS, including impurities and stabilizing additives. This section includes information on substances, mixtures, and all chemicals where a trade secret is claimed. The required information consists of:

Substances

- Chemical name.

- Common name and synonyms.

- Chemical Abstracts Service (CAS) number and other unique identifiers.

- Impurities and stabilizing additives, which are themselves classified and which contribute to the classification of the chemical.

Mixtures

- Same information required for substances.

- The chemical name and concentration (i.e., exact percentage) of all ingredients which are classified as health hazards and are:

- Present above their cut-off/concentration limits or

- Present a health risk below the cut-off/concentration limits.

- The concentration (exact percentages) of each ingredient must be specified except concentration ranges may be used in the following situations:

- A trade secret claim is made,

- There is batch-to-batch variation, or

- The SDS is used for a group of substantially similar mixtures.

Chemicals where a trade secret is claimed

- A statement that the specific chemical identity and/or exact percentage (concentration) of composition has been withheld as a trade secret is required.

Section 4: First-Aid Measures

This section describes the initial care that should be given by untrained responders to an individual who has been exposed to the chemical. The required information consists of:

- Necessary first-aid instructions by relevant routes of exposure (inhalation, skin and eye contact, and ingestion).

- Description of the most important symptoms or effects, and any symptoms that are acute or delayed.

- Recommendations for immediate medical care and special treatment needed, when necessary.

Section 5: Fire-Fighting Measures

This section provides recommendations for fighting a fire caused by the chemical. The required information consists of:

- Recommendations of suitable extinguishing equipment, and information about extinguishing equipment that is not appropriate for a particular situation.

- Advice on specific hazards that develop from the chemical during the fire, such as any hazardous combustion products created when the chemical burns.

- Recommendations on special protective equipment or precautions for firefighters.

Section 6: Accidental Release Measures

This section provides recommendations on the appropriate response to spills, leaks, or releases, including containment and cleanup practices to prevent or minimize exposure to people, properties, or the environment. It may also include recommendations distinguishing between responses for large and small spills where the spill volume has a significant impact on the hazard. The required information may consist of recommendations for:

- Use of personal precautions (such as removal of ignition sources or providing sufficient ventilation) and protective equipment to prevent the contamination of skin, eyes, and clothing.

- Emergency procedures, including instructions for evacuations, consulting experts when needed, and appropriate protective clothing.

- Methods and materials used for containment (e.g., covering the drains and capping procedures).

- Cleanup procedures (e.g., appropriate techniques for neutralization, decontamination, cleaning or vacuuming; adsorbent materials; and/or equipment required for containment/clean up)

Section 7: Handling and Storage

This section provides guidance on the safe handling practices and conditions for safe storage of chemicals. The required information consists of:

- Precautions for safe handling, including recommendations for handling incompatible chemicals, minimizing the release of the chemical into the environment, and providing advice on general hygiene practices (e.g., eating, drinking, and smoking in work areas is prohibited).

- Recommendations on the conditions for safe storage, including any incompatibilities. Provide advice on specific storage requirements (e.g., ventilation requirements)

Section 8: Exposure Controls/Personal Protection

This section indicates the exposure limits, engineering controls, and personal protective measures that can be used to minimize worker exposure. The required information consists of:

- OSHA Permissible Exposure Limits (PELs), American Conference of Governmental Industrial Hygienists (ACGIH) Threshold Limit Values (TLVs), and any other exposure limit used or recommended by the chemical manufacturer, importer, or employer preparing the safety data sheet, where available.

- Appropriate engineering controls (e.g., use local exhaust ventilation, or use only in an enclosed system).

- Recommendations for personal protective measures to prevent illness or injury from exposure to chemicals, such as personal protective equipment (PPE) (e.g., appropriate types of eye, face, skin or respiratory protection needed based on hazards and potential exposure).

- Any special requirements for PPE, protective clothing or respirators (e.g., type of glove material, such as PVC or nitrile rubber gloves; and breakthrough time of the glove material).

Section 9: Physical and Chemical Properties

This section identifies physical and chemical properties associated with the substance or mixture. The minimum required information consists of:

- Appearance (physical state, color, etc.);

- Upper/lower flammability or explosive limits;

- Odor;

- Vapor pressure;

- Odor threshold;

- Vapor density;

- pH;

- Relative density;

- Melting point/freezing point;

- Solubility(ies);

- Initial boiling point and boiling range;

- Flash point;

- Evaporation rate;

- Flammability (solid, gas);

- Partition coefficient: n-octanol/water;

- Auto-ignition temperature;

- Decomposition temperature; and

- Viscosity.

The SDS may not contain every item on the above list because information may not be relevant or is not available. When this occurs, a notation to that effect must be made for that chemical property. Manufacturers may also add other relevant properties, such as the dust deflagration index (Kst) for combustible dust, used to evaluate a dust’s explosive potential

Section 10: Stability and Reactivity

This section describes the reactivity hazards of the chemical and the chemical stability information. This section is broken into three parts: reactivity, chemical stability, and other. The required information consists of:

Reactivity

- Description of the specific test data for the chemical(s). This data can be for a class or family of the chemical if such data adequately represent the anticipated hazard of the chemical(s), where available.

Chemical stability

- Indication of whether the chemical is stable or unstable under normal ambient temperature and conditions while in storage and being handled.

- Description of any stabilizers that may be needed to maintain chemical stability.

- Indication of any safety issues that may arise should the product change in physical appearance.

Other

- Indication of the possibility of hazardous reactions, including a statement whether the chemical will react or polymerize, which could release excess pressure or heat, or create other hazardous conditions. Also, a description of the conditions under which hazardous reactions may occur.

- List of all conditions that should be avoided (e.g., static discharge, shock, vibrations, or environmental conditions that may lead to hazardous conditions).

- List of all classes of incompatible materials (e.g., classes of chemicals or specific substances) with which the chemical could react to produce a hazardous situation.

- List of any known or anticipated hazardous decomposition products that could be produced because of use, storage, or heating. (Hazardous combustion products should also be included in Section 5 (Fire-Fighting Measures) of the SDS.)

Section 11: Toxicological Information

This section identifies toxicological and health effects information or indicates that such data are not available. The required information consists of:

- Information on the likely routes of exposure (inhalation, ingestion, skin and eye contact). The SDS should indicate if the information is unknown.

- Description of the delayed, immediate, or chronic effects from short- and long-term exposure.

- The numerical measures of toxicity (e.g., acute toxicity estimates such as the LD50 (median lethal dose)) – the estimated amount [of a substance] expected to kill 50% of test animals in a single dose.

- Description of the symptoms. This description includes the symptoms associated with exposure to the chemical including symptoms from the lowest to the most severe exposure.

- Indication of whether the chemical is listed in the National Toxicology Program (NTP) Report on Carcinogens (latest edition) or has been found to be a potential carcinogen in the International Agency for Research on Cancer (IARC) Monographs (latest editions) or found to be a potential carcinogen by OSHA

Section 12: Ecological Information (non-mandatory)

This section provides information to evaluate the environmental impact of the chemical(s) if it were released to the environment. The information may include:

- Data from toxicity tests performed on aquatic and/or terrestrial organisms, where available (e.g., acute or chronic aquatic toxicity data for fish, algae, crustaceans, and other plants; toxicity data on birds, bees, plants).

- Whether there is a potential for the chemical to persist and degrade in the environment either through biodegradation or other processes, such as oxidation or hydrolysis.

- Results of tests of bioaccumulation potential, making reference to the octanol-water partition coefficient (Kow) and the bioconcentration factor (BCF), where available.

- The potential for a substance to move from the soil to the groundwater (indicate results from adsorption studies or leaching studies).

- Other adverse effects (e.g., environmental fate, ozone layer depletion potential, photochemical ozone creation potential, endocrine disrupting potential, and/or global warming potential).

Section 13: Disposal Considerations (non-mandatory)

This section provides guidance on proper disposal practices, recycling or reclamation of the chemical(s) or its container, and safe handling practices. To minimize exposure, this section should also refer the reader to Section 8 (Exposure Controls/Personal Protection) of the SDS. The information may include:

- Description of appropriate disposal containers to use.

- Recommendations of appropriate disposal methods to employ.

- Description of the physical and chemical properties that may affect disposal activities.

- Language discouraging sewage disposal.

- Any special precautions for landfills or incineration activities

Section 14: Transport Information (non-mandatory)

This section provides guidance on classification information for shipping and transporting of hazardous chemical(s) by road, air, rail, or sea. The information may include:

- UN number (i.e., four-figure identification number of the substance)

- UN proper shipping name

- Transport hazard class(es)

- Packing group number, if applicable, based on the degree of hazard

- Environmental hazards (e.g., identify if it is a marine pollutant according to the International Maritime Dangerous Goods Code (IMDG Code)).

- Guidance on transport in bulk (according to Annex II of MARPOL 73/78 and the International Code for the Construction and Equipment of Ships Carrying Dangerous Chemicals in Bulk (International Bulk Chemical Code (IBC Code)).

- Any special precautions which an employee should be aware of or needs to comply with, in connection with transport or conveyance either within or outside their premises (indicate when information is not available).

Section 15: Regulatory Information (non-mandatory)

This section identifies the safety, health, and environmental regulations specific for the product that is not indicated anywhere else on the SDS. The information may include:

- Any national and/or regional regulatory information of the chemical or mixtures (including any OSHA, Department of Transportation, Environmental Protection Agency, or Consumer Product Safety Commission regulations)

Section 16: Other Information

This section indicates when the SDS was prepared or when the last known revision was made. The SDS may also state where the changes have been made to the previous version. You may wish to contact the supplier for an explanation of the changes. Other useful information also may be included here.

Employer Responsibilities

Employers must ensure that the SDSs are readily accessible to employees for all hazardous chemicals in their workplace. This may be done in many ways. For example, employers may keep the SDSs in a binder or on computers as long as the employees have immediate access to the information without leaving their work area when needed and a back-up is available for rapid access to the SDS in the case of a power outage or other emergency. Furthermore, employers may want to designate a person(s) responsible for obtaining and maintaining the SDSs. If the employer does not have an SDS, the employer or designated person(s) should contact the manufacturer to obtain one.

SDS Signage

Safety Momont msds

References

OSHA, 29 CFR 1910.1200(g) and Appendix D. United Nations Globally Harmonized System of Classification and Labelling of Chemicals (GHS), third revised edition, United Nations, 2009. These references and other information related to the revised Hazard Communication Standard can be found on OSHA’s Hazard Communication Safety and Health Topics page, located at:http://www.osha.gov/dsg/hazcom/index.html.

List of SDS (MSDS) given below:

Internet Resources for MSDS

General Sites

These sites have large collections of MSDS and are a good place to start your search.

| Internet Site |

Number of MSDS |

MSDS Solutions

3E Company |

4,500,000 |

Free trial, but allows only 5 free downloads. Registration/login is required to view the sheets which are available in a variety of (M)SDS formats (GHS, OSHA, ANSI, WHMIS) and file formats (HTML, PDF, text). 200,000+ available in French. MSDS download “blocks” available on a fee basis. Site may not operate correctly with popup blockers enabled. |

| MSDSonline |

3,500,000+ |

Registration allows a free trial search that “is limited in use and intended only as a test of the MSDSonline database.” GHS, OSHA, DOT, ANSI and WHMIS compliant sheets in PDF format. 10,000+ new/updated sheets are added each week. The site also offers a suite of compliant MSDS access, management and deployment solutions. |

| MSDSXchange |

1,000,000+ |

(Temporarily or permanently offline as of mid-August 2016). Like a file sharing system for (M)SDS’s. Search the Xchange database or manufacturer’s web sites – or even browse those in alphabetical order. Adding ~10,000 additional sheets/month. Free unlimited storage/management binder is included (registration required). Sheets in PDF format; most appear to be ANSI compliant. |

| MSDSprovider |

1,000,000+ |

Requires free registration with email confirmation. Free users can search, save and print SDS documents by product or manufacturer keyword; Premium (pro) features include ability to assign/track locations, create SDS binders and more. Sheets in PDF format; most appear to be ANSI/GHS compliant. |

| Seton MSDS Hazard Communication Library |

500,000 |

Full text searchable – At the moment, this site is undergoing an upgrade. If it comes on-line soon, let us know. You can also purchase an improved version of this collection that has a great bang for the buck. |

| SFS Chemical Safety |

250,000 |

Search by name, manufacturer, and/or CAS number. Approximately 80% are SDS vs MSDS, with 5,000 new sheets being added weekly. Most are in PDF file format. |

Vermont SIRI at

hazard.com |

180,000 |

No longer maintained; much of the data set is over 10 years old. Either select a letter A-Z to browse manufacturers alphabetically (for sheets not in the SIRI collection) or do a full-text keyword search in the SIRI MSDS database. Mostly old OSHA-style sheets,all in text file format. Lots of additional safety links and info. |

PerkinElmer ChemBioFinder.com

(formerly CambridgeSoft) |

153,000 |

Registration required. A substructure-searchable small-molecule database with 2D and 3D structures, some of which have (M)SDS links. Contains info useful for linking to other datbases such as SMILES, InChI and InChIKey strings for 2 million compounds |

| University of Akron |

30,209 |

Login with “guest” as the username and leave the password blank. Keyword search (see the Help button on that page for tips). Most information returned are now (M)SDS’s from various manufacturers. /td> |

| ChemExper |

10,000 |

Belgium. Search for chemical by name, molecular formula, CAS number, InChI, InChIKey or SMILES. When you find the one you want click on the name of the chemical. Some of the results have (M)SDS links or link to the manufacturer’s web site where you can then inquire about or find the sheet you want. |

| Conform-Action Data Systems |

5,000 |

Sample database that dynamically produces English or French ANSI,OSHA and WHMIS-compliant sheets. User can select HTML or PDF format. Also produces PDF labels. |

| Iowa State University |

295 |

Aug-2106: Server has gone off-line; we’re trying to track down the new home. Typical undergraduate laboratory chemicals. Select from alphabetical list. 16-part ANSI-style sheets in HTML format. |

[Top] [General Sites] [Governmental] [Chemical Companies] [Pesticides] [Misc]

Government and Non-Profit Sites

The first two sites return all sorts of chemical information; the remainder are written more for humans rather than corporate lawyers and are good sites for non-chemists to find information.

Safety Emporium Makes MSDS Compliance Easy!!

MSDS binders, centers, labels, software, posters, training materials, signs and more! |

|

| Internet Site |

Number of MSDS |

PubChem

US National Institutes of Health |

48,700,000+ |

These are not SDS, but if you search for a chemical under Compound or Substance, it will return an incredible wealth of information on the material. Results include pharmacological action/classification, safety/toxicology, literature links, physical data and lots more. Bioassay and structure searches also available. Their Laboratory Chemical Safety Summary (LCSS) system is particular use for laboratory safety. |

Chemspider

Royal Society of Chemistry |

35,000,000+ |

These are not SDS, but if you search for a chemical, it will return information including properties, sources, and links to journal articles, web articles, and (M)SDS’s. Nice advanced search options, including structural. |

Scorecard

Environmental Defense Fund |

11,200 |

These are not SDS’s, but the site returns data on human health hazards, risk assessment values, rankings, uses, environmental release information and regulatory coverage. Search by name or CAS #. HTML format. Good for community activists. |

| OHSAH MSDS Database |

10,000+ |

Unique site focused on healthcare agencies such as hospitals and doctor’s offices. All sheets are less than 3 years old and are WHMIS compliant PDF files. Handy popups in results with additional info. Search by product and/or manufacturer. Site has a handy MSDS request form for items not currently in the database (for those within the BC healthcare system only). |

| U.S. EPA Substance Registry Services (SRS) |

6,864 |

Search US EPA information by name or CAS number. These are not SDS, but may contain useful safety/environmental info. Approximately 320 sheets are EPA, the rest are links to other sites in this section such as Scorecard (above). The full list is available as well. |

| North American Emergency Response Guidebook |

3,714 |

Not SDS,but guide for emergency services personnel at transportation incidents involving hazardous materials. Sheets cover specific classes of materials, not all 3,714 chemcials. Download link is http://www.phmsa.dot.gov/staticfiles/PHMSA/DownloadableFiles/Files/Hazmat/ERG2016.pdf. Also available in Spanish (PDF download) and as a mobile app for iPhone and Android. |

Household Products Database

National Library of Medicine

(National Institutes of Health) |

~2,000 chemicals

~12,000 brands |

For household consumers. Has access to items added since 2007. Uses (M)SDS info to list/explain health effects, composition etc. of various consumer brands. Search/browse by brand, category, chemical name, CAS number, health effects etc. Includes links to appropriate toxicological information at TOXNET and manufacturer contact info so you can make informed consumer decisions. |

The National Toxicology Program

(National Institutes of Health) |

2,000+ |

Searchable health and safety database. Search by CAS number or all/part of the chemical name. Not SDS’s, but a lot of (M)SDS-related information. |

The National Toxicology Program

(National Institutes of Health) |

243 |

13th annual report on known and suspected carcinogens (released October 2, 2014). Not MDS, but great info. Also details how a chemical comes to be listed as a carcinogen. Questions and Answers about the 13th RoC gives a good overview of the RoC. |

| New Jersey Hazardous Substance Fact Sheets (NJHSFS) |

1,700+ English

900+ Español |

Right to Know site. Plain English descriptions of common household,workplace and environmental chemicals (great for non-chemists). Browse English/Spanish list or type in by name. PDF format. |

| CDC/NIOSH/WHO International Chemical Safety Cards |

~1,700 |

Select one of 13 different languages. English has U.S. and International versions. Not strictly SDS,but close. Good for “shop floor” level of understanding. HTML format. |

| International Agency for Research on Cancer,IARC |

900 |

Not (M)SDS’s, but monograph reports on cancer risks to humans by a variety of agents. Enter a chemical name or CAS number in the search box. Results in HTML format. Related publications are also available. |

| OSHA/EPA Occupational Chemical Database |

801 |

These are not (M)SDS, but a database of physical properties, exposure guidelines, NIOSH Pocket Guide info, and DOT emergency response data. Very useful for MSDS authors. Search by name or CAS number or browse A-Z lists. HTML format. |

| NIOSH Pocket Guide to Chemical Hazards |

677 |

Succinct tabular summaries of MSDS-type information for all materials with NIOSH exposure limits or OSHA permissible exposure limits (PEL’s). Spanish version “under construction”. Select from A-Z list or CAS number list. HTML format. |

| Agency for Toxic Substances and Disease Registry |

194 |

ToxFAQ™’s categorized by name A-Z. Available in both English and Spanish. Not (M)SDS, but a practical Q&A approach to the health effects of chemicals. Longer Public Health Statements and additional toxicology information available. Viewable in both HTML and PDF formats. |

| Health Canada |

192 |

Pathogen Safety Data Sheets (PSDS) for biohazardous agents (i.e infectious microorganisms,including anthrax = bacillus anthracis). WHMIS-compliant HTML files. Also available as a mobile app for most platforms. |

| American Chemical Society |

60 |

Chemistry Laboratory Information Profiles (CLIPs) taken from the Journal of Chemical Education. These are not MSDS’s, but they can assist instructors in determining proper laboratory precautions. PDF files. |

| Gulf War Veterans Resource Pages |

6 |

Scroll down to the Appendix for links to military unique MSDS on Mustard (HD, THD),Tabun (GA),Sarin (GB), Soman (GD), VX (nerve agent) and Lewisite (HT) – hopefully you won’t need to use these! HTML files in OSHA-compliant format. |

[Top] [General Sites] [Governmental] [Chemical Companies] [Pesticides] [Misc]

Chemical Manufacturers and Suppliers

The best place to start if you have a bottle from that particular manufacturer!

Safety Emporium Makes MSDS Compliance Easy!!

MSDS binders, centers, labels, software, posters, training materials, signs and more! |

|

| Internet Site |

Number of MSDS |

Sigma, Aldrich

Fluka, Supelco, RdH-Lab |

200,000+ |

Search for the product and then click on the SDS link to display GHS-compliant sheet in PDF format. Versions are available in 50 languages. If you know the product # already use this link. |

| Fisher Scientific, Alfa Aesar (US) |

70,000+ |

Search by catalog number, CAS number, chemical name or supplier part number. GHS-compliant SDS in PDF format. Fisher has other global sites, too. |

| Abcam PLC |

70,000+ |

Biochemical supplies – antibodies, proteins, peptides, assay kits and more. Search for product and then click on SDS link. Sheets are GHS-compliant and are in PDF format. |

| VWR Scientific Products |

40,000+ |

Search by keyword, manufacturer name, part number or other fields. Sheets are GHS-compliant as PDF files. |

| EMD Millipore |

12,000+ |

Search by catalog number only. Alternatively, search the catalog for a product and then the SDS link on the right side under “About this product”. GHS-compliant sheets in PDF format; some are available in multiple language/regional versions. |

| ScienceLab.com |

4,570 |

Alphabetical listing that does not ignore numbers or parentheses. Colorful ANSI style sheets that are not necessarily GHS-compliant in PDF format. Note: This company apparently has an F rating by the Better Business Bureau. User/buyer beware. |

| Roche Applied Science |

3,600? |

Searchable by product name or catalog number. Select from SDS or instructions for use document in search results. PDF format. |

| Airgas |

3,283 |

SDS on their pure gases, gas mixtures, and hard goods. Color PDF documents in GHS format. |

| Gelest Inc |

2,408 |

Products include silanes and silicones; germanium and tin compounds; and metal alkoxides and diketonates. Search for product and then click the SDS link. PDF file in GHS-compliant format. |

Advantor Performance Materials

(formerly J. T. Baker,Inc and Mallinckrodt Laboratory Chemicals) |

2,100 |

Search by product number, product name, or CAS number. Click SDS/MSDS link from the product page. GHS-compliant sheets in PDF format. Available in multiple languages. |

| Selleck Chemicals |

~2,000 |

Search through their product categories for the biochemical product of interest and then click on the MSDS link under the blue Validation & Quality Control tab. EU/ANSI-compliant sheets in HTML format. |

| Air Products and Chemicals,Inc. |

1,862 |

A variety of search options for GHS-compliant SDS’s in PDF format. Also available in multiple languages/countries. Requires the use of cookies. Also view their Safetygrams. |

| Lamotte Company |

1,712 |

SDS on their water,soil and air analysis reagents and test kits. Enter product code number to find the SDS. ANSI-compliant sheets in PDF format. |

| Eastman Kodak |

1,500 |

Search by product name or catalog number. SDS available in a variety of different country/language versions. GHS-compliant sheets in PDF format. |

| E. I. du Pont de Nemours and Company |

1,400+ |

SDS on their products. Search by product name, SDS number or manufacturer name. Click on the little icon in the search result and then select a country and language. GHS-compliant sheets in PDF format. Note: DuPont is merging with Dow and splitting out several companies… |

| Science Stuff, Inc. |

1,400 |

SDS for science supplies, common lab chemicals etc. for education, hobbyists and others. Browse their A-Z listing or catalog, select an item and click on NFPA diamond icon for SDS. ANSI-compliant sheets in PDF format. |

| Flinn Scientific |

1,300 |

Flinn focuses on science instructors. Search by keyword or select from an alphabetical list. GHS-complaint sheets in PDF format. |

| Redox Chemicals Pty Ltd |

1,158 |

Australia. SDS on their products using one simple terse search box. GHS-compliant sheets in PDF format |

| Solvay Rhodia |

1,000+ |

Search for product you desire and then select country/region from the pulldown menu to provide the link to the SDS. |

| ExxonMobil Corporation |

750 |

SDS on their products. Search by key product/trade name or product code. RTF sheets in GHS format. Includes U.S., Australian, and French/English Canadian versions. |

| Electronic Space Products International |

425 |

(M)SDS on high purity metal products,inorganic compounds,alloys,sputtering targets. Alphabetical list of HMTL sheets in the various formats – not all are not compliant with current OSHA regulations. |

| Matheson Tri-Gas,Inc. |

419 |

SDS on their gas products. Search by chemical name, CAS number, SDS number, format, or language. GHS-compliant, color SDS in PDF format. 9 sheets are also available in Spanish. |

| Dojindo Molecular Technologies (Japan) |

396 |

Search for the product and then click on the MSDS link. Versions also available for Japanese, Chinese and European markets. GHS-compliant sheets in PDF format. |

| Air Liquide |

387 |

SDS on their gas products. Click on link to their SDS supplier service. GHS-compliant sheets in PDF format. |

| United Laboratories |

370 |

U.S. and Canadian SDS on their maintenance and housekeeping products. One long list ordered by product number. GHS compliant sheets in PDF format. |

Affymetrix

(formerly USB Corporation) |

358 |

SDS on their biochemicals, reagents, modifying enzymes and sequencing products. Use search box with “MSDS” and product you want or browse to the product, select the “Technical Documentation” of “Documents” tab to open that and then click on the MSDS link. GHS-compliant sheets in PDF format. |

| Bristol-Myers Squibb |

338 |

SDS on their drug and personal care products. Search by name, synonym, manufacturer and/or language (16 available). GHS-compliant sheets as scanned documents in PDF files. |

BD Diagnostics Systems

(formerly Difco) |

274 |

Microbiology and culture media-related products. Select a language and enter the BD Catalog number. Alternatively, search for the product at http://search.bd.com/, then click on the MSDS link under Related Documents in the right sidebar. GHS-compliant, color sheets in PDF format with the option to download multiple sheets in ZIP format. |

Linde Gases

includes BOC Gases |

226 |

SDS on their gases and gas mixtures. Search for English, Spanish, and Candian French GHS-compliant sheets in PDF format. This is their US site; additional countries are also available. |

| Alken-Murray Corporation |

127 |

SDS on pollution control products (degreasers, microbials, antiodorants etc.). GHS-compliant, color sheets in HTML format. |

| Accepta Ltd. |

~100 |

SDS on their waste water treatment and specialty chemicals. Find a product using the search box or site navigation, click on the blue info box and then click on the SDS link. ANSI-compliant sheets in PDF format. |

[Top] [General Sites] [Governmental] [Chemical Companies] [Pesticides] [Misc]

Pesticides (herbicides, insecticides, fungicides, nematicides, rodenticides etc.) Includes fertilizers.

A great place to start for farmers, home gardeners or someone who got too close to a crop dusting plane.

400,000 SDS’s in your shirt pocket Incredible, but true!

And you can install them on your company-wide network at no extra charge! |

|

| Internet Site |

Number of MSDS |

| Crop Data Management Systems |

4,400 |

SDS and pesticide labels from 120 manufacturers. List by manufacturer or search by product name to get SDS and and labels as PDF files in varying formats. Each manufacturer listing includes its web site address. |

| DoMyOwnPestControl.com |

2,261 |

Pesticide and adjuvant (M)SDS’s and labels. Alphabetical multi-age list to browse or search. Various formats. |

| Greenbook |

1,500 |

Pesticide and adjuvant MSDS’s and labels. Regular updates from participating manufacturers. Nicely compact PDF files (2-3 pages and proofread!) in varying formats. Quick search by name or active ingredients. Requires free registration. |

| EXTOXNET |

193 |

Pesticide Information Profiles (not MSDS); many are out of date, however. Lots of other useful toxicology information and manufacturer links. Search or browse. |

| Dow AgroSciences |

170 |

A list of products, each with a label and SDS link. GHS-compliant sheets in PDF format. For other countries start at http://www.dowagro.com/products/label/. Note: Look here for Rohm and Haas sheets (Dow bought their ag products in June 2001). |

Syngenta Crop Protection,Inc.

(Merger of Novartis and Zeneca)

Crop Protection Chemicals

and Professional Products |

216

97 |

SDS and labels for a) Crop protection and b) Professional turf/ornamental products. Select a product label from a pulldown menu, click Submit; click on “View SDS” in the label display. GHS-compliant sheets in PDF format. |

Everris (ICL Group)

(formerly Scotts Professional Horticulture) |

~80 |

SDS’s on their commercial (but not consumer) agricultural products including fertilizers, herbicides, fungicides, miticides and surfactants. Search by Product Name / Product Code / Analysis; SDS links are not provided for all products. GHS-compliant sheets in PDF format. Multiple languages available. |

| DuPont Crop Protection, Canada |

80 |

SDS, bulletins and labels for fungicides, herbicides and insecticides. Scroll to bottom of pae for SDS Finder. Select a product the list of categories and then select MSDS or label link. GHS-compliant sheets in PDF format. Multiple languages available. |

| Bayer CropScience |

66 |

Select product from the “View All Labels/MSDS” pulldown menu on left side. Very detailed GHS-compliant sheets in PDF format. Much additional product info also available on this site/page. |

| FMC Agricultural Products |

47 |

Termiticides, insecticides,miticides, flea and ant control products. GHS-compliant PDF sheets as well as labels. |

| Bell Laboratories, Inc. |

40 |

Bell manufactures rodenticides. Select from over 3 dozen country-specific sheets. GHS-compliant sheets in PDF format. |

[Top] [General Sites] [Governmental] [Chemical Companies] [Pesticides] [Misc]

Miscellaneous

Look here for manufacturers whose primary business is not chemicals. Industrial suppliers, pharmacology, MSDS suppliers and more can be found here.

Right to Know Compliance Centers w/ GHS-Compliant Binders, Racks and Boards

Get these and other OSHA compliance materials at Safety Emporium! |

|

| Internet Site |

Number of MSDS |

| Interactive Learning Paradigms, Incorporated |

2 |

Hey…that’s us! Contains links to other sites that serve MSDS. |

| Aubuchon Hardware |

5,000+ |

Aug 2016: missing; we have an email out to them. SDS for products commonly sold in hardware stores. First select a search option – Manufacturer model#, UPC, Product Name, Vendor Name, or Aubuchon SKU. Then type in the search term or phrase and hit Search. PDF files in various formats. |

Sealed Air

(formerly JohnsonDiversey)

(merger of Johnson Wax Professional and DiverseyLever) |

4,000 |

Floor cleaners, waxes and related products. Search to get GHS-compliant sheets in PDF format. Additional country/languages are available as well. Includes Butcher’s products. |

| W. W. Grainger, Inc. |

3,734 |

MSDS on their myriad industrial products. Can search by Grainger item number,manufacturer,common name,model number or full text. HTML sheets in GHS format. |

| OnTimeSupplies.com |

3,500 |

SDS for batteries, office supplies and janitorial cleaning products. Search by product name or SKU and then click MSDS link. GHS-compliant sheets in PDF format. |

| Procter and Gamble |

2,947 |

SDS on their consumer and professional line of personal, health, chemical and cleaning supplies. Select by general category and then select the sheet you desire. GHS-compliant sheets in PDF format. |

| Loctite Corporation |

1,838 |

SDS on their sealants,adhesives and coatings. Search by product name, trade name or item number. GHS-compliant sheets in PDF format. Additional choices for Canada and Mexico-localized sheets. Not working reliably for us (no search results). |

| Cytec Industries |

1,633+ |

Registration required (for no good reason). Includes building blocks, phosphines, polymer additives, monomers, surfactants, resins, water, paper, mining and alumina. Available for multiple countries. Search by name or product number. PDF files in GHS-compliant format. |

| Xerox Corporation |

~500 |

Enter an MSDS number, part number or key word in the search box OR select a product family and then specific product which will take you to SDS’s that pertain to the product. GHS-compliant sheets in PDF format. Additional environmental/health/safety info are also available. |

| The Sherwin-Williams Company |

497 |

SDS on their paint products. Enter name or product number. Then click on the MSDS icon to retrieve an GHS-compliant sheets in PDF format. |

| ABC Compounding |

450 |

Cleaners and related products. Browse alphabetically or through categories to view individual products and then click the MSDS link to view ANSI-compliant sheets in PDF format. |

Lincoln Electric

Airco + Murex,too |

356 |

SDS for welding and cutting products (electrodes, wire, solder, flux, consumables,etc.). Select product name from pulldown menu or search by material number. Choose from list to GHS-compliant sheets in PDF format. Some are 25 pages long! |

| Johns Manville |

265 |

SDS on their building materials, commercial/industrial roofing, reinforcements and filtration media from multiple countries. Search only; may be easier to browse to a specific product and then select the SDS link. SDS’s for 503 products; not all sheets are unique. PDF files in GHS-compliant format. Available in German, French and Spanish. |

| SPI Supplies |

258 |

SDS on microscopy and histology chemicals. Select from alphabetical product list. GHS-compliant sheets as PDF files. |

| Rentokil Initial plc |

200 |

Medical, textile, hygiene, tropical plant, pest control, property care etc. Select a product division to see a list and then click on product to see GHS-compliant color sheets in PDF format. |

| Liberty Natural Products |

181 |

SDS on botanical extracts. Navigate to a specific product and then click on the MSDS link. OSHA-style in HTML format. |

| Hewlett-Packard |

175 |

SDS for toners,inkjet and laser printer supplies. Select product type and then select from list. GHS-compliant sheets in PDF format. Available in dozens of languages/regions. |

| Falcon Safety Products, Inc. |

150 |

SDS for dusters,office care,image care,marine,safety and photographic products. Search by Model # or CAS# only; alternatively, browse to a product and then click on the MSDS link. GHS-compliant color sheets, most in PDF format. |

| Smooth-On, Inc. |

150 |

SDS for mold making supplies, urethane and silicone rubber, urethane and epoxy casting resins. Browse categories/list or ue the Quick Find to obtain GHS-compliant color sheets in PDF format. |

| The Essential Oil Company |

150 |

MSDS on their essential, fixed, and perfume oil products. Old OSHA-style sheets in HTML format. Note: These are not GHS-compliant sheets because they lack OSHA-required elements. |

| Oatey Plumbing Supplies |

~150 unique |

SDS on Oatley, Harvey, Hercules, and United Elchem plumbing products. GHS-compliant sheets in PDF format. Also available in French. |

| 5 Star Xtreme Autobody Products |

138 |

SDS on automotive repair products such as paints, primers, activators, solvents etc. Select product on the site and then click on the appropriate SDS link. GHS-compliant sheets for US and Canada in PDF format. |

| General Paint |

100+ |

Click on the product line and then the individual product to get PDF files in OSHA format. Old-style OSHA MSDS in PDF format. Note: These are not GHS-compliant sheets because they lack OSHA-required elements. |

| Elmer’s Products, Inc. |

~100 unique sheets |

SDS on their arts & crafts,teacher’s, woodworking, home repair, pro bond and kid’s glue/adhesive products. Search alphabetically, by keyword, or by category and then click the MSDS link in the product list. GHS-compliant HTML files. Many sheets are redundant. |

Glidden

(ICI Paints North America) |

88 |

SDS on their interior and exterior paints. Select from scrolling list ordered by product code or number. GHS-compliant sheets in PDF format. Technical datasheets are also available. |

| Cargille Laboratories |

88 |

SDS on microscopy optical liquids. Must disable popup blockers to see sheets. Select desired product from appropriate pulldown menu to view OSHA-style sheets as PDF files. strong>Note: These are not GHS-compliant sheets because they lack OSHA-required elements. |

STIC-ADHESIVE Products Co.

MIL-SPEC Adhesives |

61 |

Click on the SDS link for the epoxy, urethane, adhesive etc. product of your choice. ANSI-style sheets in PDF format. strong>Note: These are not GHS-compliant sheets because they lack OSHA-required elements. |

| Cabot Stains |

45 |

SDS on their stains and related products. Select a product, click on the US or Canadian version to obtain GHS-compliant sheets in PDF format. |

| Winchester Ammunition (Olin Corporation) |

34 |

SDS on their centerfire handgun and rifle, shotshell, rimfire, components, industrial products, military products, and explosives. GHS-compliant sheets in PDF format. |

| Amerex Corporation |

24 |

SSDS for fire extinguishing media. GHS-compliant sheets in PDF format. |

| Hillyard |

22 |

SDS on their cleaning and stripping products. Browse to a product and click on the SDS or Technical Data link on the product page. GHS-compliant sheets in PDF format. |

| Summers Optical |

20 |

SDS for optical cements and adhesives for military,commercial,and aerospace usage. Most are GHS-compliant sheets in PDF format. |