Contents

Confined space

What is confined space:

Generally speaking, a confined space is an enclosed or partially enclosed space that:

- is not primarily designed or intended for human occupancy

- has a restricted entrance or exit by way of location, size or means

- Can represent a risk for the for the health and safety of anyone who enters, due to one or more of the following factors:

- its design, construction, location or atmosphere

- the materials or substances in it

- work activities being carried out in it, or the

- mechanical, process and safety hazards present

Confined spaces can be below or above ground. Confined spaces can be found in almost any workplace. A confined space, despite its name, is not necessarily small. Examples of confined spaces include silos, vats, hoppers, utility vaults, tanks, sewers, pipes, access shafts, truck or rail tank cars, aircraft wings, boilers, manholes, manure pits and storage bins. Ditches and trenches may also be a confined space when access or egress is limited.

hazards in a confined space?

All hazards found in a regular work space can also be found in a confined space. However, they can be even more hazardous in a confined space than in a regular work site.

Hazards in confined spaces can include:

- Poor air quality: There may be an insufficient amount of oxygen for the worker to breathe. The atmosphere might contain a poisonous substance that could make the worker ill or even cause the worker to lose consciousness. Natural ventilation alone will often not be sufficient to maintain breathable quality air.

- Chemical exposures due to skin contact or ingestion as well as inhalation of ‘bad’ air.

- Fire Hazard: There may be an explosive/flammable atmosphere due to flammable liquids and gases and combustible dusts which if ignited would lead to fire or explosion.

- Process-related hazards such as residual chemicals, release of contents of a supply line.

- Noise.

- Safety hazards such as moving parts of equipment, structural hazards, entanglement, slips, falls.

- Radiation.

- Temperature extremes including atmospheric and surface.

- Shifting or collapse of bulk material.

- Barrier failure resulting in a flood or release of free-flowing solid.

- Uncontrolled energy including electrical shock.

- Visibility.

- Biological hazards.

Confined space more hazardous than working in other work spaces:

Many factors need to be evaluated when looking for hazards in a confined space. There is smaller margin for error. An error in identifying or evaluating potential hazards can have more serious consequences. In some cases, the conditions in a confined space are always extremely hazardous. In other cases, conditions are life threatening under an unusual combination of circumstances. This variability and unpredictability is why the hazard assessment is extremely important and must be taken very seriously each and every time one is done.

Some examples include:

- The entrance/exit of the confined space might not allow the worker to get out in time should there be a flood or collapse of free-flowing solid.

- Self-rescue by the worker is more difficult.

- Rescue of the victim is more difficult. The interior configuration of the confined space often does not allow easy movement of people or equipment within it.

- Natural ventilation alone will often not be sufficient to maintain breathable quality air. The interior configuration of the confined space does not allow easy movement of air within it.

- Conditions can change very quickly.

- The space outside the confined space can impact on the conditions inside the confined space and vice versa.

- Work activities may introduce hazards not present initially.

Confined Space Hazard Assessment and Control Program:

To manage the risks associated with working in confined spaces, a Confined Space Hazard Assessment and Control Program should be developed and implemented. A Confined Space Hazard Assessment and Control Program, specific for the work being conducted, should be written for work in each and every confined space.

A Confined Space Hazard Assessment and Control Program should include the following:

- Description of roles and responsibilities of each person or party (e.g., employer, supervisor, workers, attendant, and emergency response team).

- Advice on how to identify confined spaces.

- The identification and assessment of all potential hazards that may exist at the beginning of the work as well as those that may develop because of the work activities.

- A plan to eliminate or control all identified hazards.

- Training program for all the workers that will enter into the confined spaces.

- The establishment of an entry permit system for each entry into a confined space.

- Development of an emergency plan complete with training and equipment in case an unforeseen situation occurs.

- An emergency response system.

- Program review whenever there is a change in circumstances or at least annually, to identify program weaknesses and make any necessary changes to the program.

- Record and documentation control.

Entry Permit System:

An Entry Permit is an administrative tool used to document the completion of a hazard assessment for each confined space entry. Someone fully trained and experienced in confined space work should complete the Entry Permit.

Before entering a confined space, an entry permit should be written. It should contain at least the following information:

- The length of time the permit is valid for.

- The name(s) of the worker(s) that are authorized to enter the confined space.

- The name(s) of the attendant(s) (safety watch) and/or supervisor.

- The location and description of the confined space.

- The work that is to be done in the confined space.

- Possible hazards that may be encountered inside and outside the space.

- Possible hazards that may develop during the work activity.

- The date and time of entry into the confined space and the anticipated time of exit.

- The details of any atmospheric testing done of the confined space – when, where, results, date monitoring equipment was last calibrated. Ideally, calibration would be done just before each use. If this is not possible, follow the equipment manufacturers guidelines for frequency of calibration.

- Hazard control measures, including the use of mechanical ventilation and other protective equipment needed and any other precautions that will be followed by every worker who is going to enter the confined space.

- Means of communication between the persons working in the confined space and the attendant.

- Emergency plan, and the protective equipment and emergency equipment to be used by any person who takes part in a rescue or responds to other emergency situations in the confined space.

- A signature of a worker who did the confined space air testing. The signature on the permit would indicate that adequate precautions are being taken to control the anticipated hazards.

- Authorization signature by the supervisor certifying that the space has been properly evaluated, prepared, and it is safe for entry and work.

The entry permit should be posted at the confined space and remain so until the work is completed. The employer should keep a copy of the completed permit on file.

What should happen when work is being done in a confined space?

There should be warning signs to prevent unauthorized entry to the confined space.

Anyone working in a confined space must be constantly alert for any changing conditions within the confined space. In the event of an alarm from monitoring equipment or any other indication of danger, workers should immediately leave the confined space.

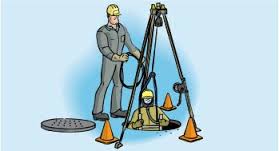

Another worker, the attendant (also known as the Safety Watch or Standby), is posted outside the confined space and continuously monitors the workers inside the confined space. The Safety Watch has the following duties:

- Understands the nature of the hazards that may be found inside the particular confined space and can recognize signs, symptoms and behavioral effects that workers in the confined space could experience.

- Monitors the confined space and surrounding area and is on the look out for dangerous conditions.

- Remains outside the confined space and does no other work which may interfere with their primary duty of monitoring the workers inside the confined space.

- Maintains constant two-way communication with the workers in the confined space.

- Orders the immediate evacuation if a potential hazard, not already controlled for, is detected.

- Calls for emergency assistance immediately if an emergency develops.

- Is immediately available to provide non-entry emergency assistance when needed.

- Can provide entry rescue only after the most stringent precautions are taken and another Safety Watch is immediately available.

Should a worker leave a confined space for a short time (for example, coffee break, getting additional material for their work.), the confined space should be re-tested before the worker re-enters. If the confined space has been continuously monitored by equipment that can show the details of the atmosphere during the time absent from the confined space and this information can be seen from outside the confined space, it can be re-entered without retesting. If there is not continuous air monitoring then the hazard assessment needs to be repeated.

No confined space should be closed off until it has been verified that no person is inside it.

After exiting the confined space, the time of exit should be noted on the entry permit.

Emergency response precautions:

If a situation arises where there is a hazardous condition and the worker does not leave or is unable to leave the confined space, rescue procedures should be begin immediately.

The Safety Watch is qualified in confined spaces rescue procedures and will be available immediately outside the confined space to provide emergency assistance if needed. The Safety Watch should be familiar with the structural design of the confined space. The Safety Watch is in constant communication with the worker inside the confined space and will:

- Have an alarm for calling for help.

- Have all required rescue equipment (for example, safety harnesses, lifting equipment, a lifeline) immediately available and be trained in its use.

- Hold a basic first aid certificate.

- Can do Cardiopulmonary Resuscitation (CPR).

The detailed plan for emergency response to an injury or other emergency within the confined space should be described in detail in the Confined Space Hazard Assessment and Control Program.

Rescue the victims from outside of the confined space, if possible. No other worker should enter a confined space to attempt a rescue unless that worker is fully trained in the rescue procedures and is wearing the appropriate personal protective equipment. More than 60% of deaths in confined spaces are would-be rescuers, who are not fully trained and adequately equipped.

Another worker qualified in confined spaces rescue procedures must be present outside the confined space before the first rescuer enters the confined space. Do not use the same air as the confined space workers you are rescuing. Wear SCBA (self contained breathing apparatus) or supplied air respirator with an escape bottle.

Training important for workers:

Yes, appropriate training is extremely important to working safely in confined spaces. Hands-on training should be an essential part of the confined space training.

Every worker that enters a confined space must be fully trained on the following:

- Recognition and identification of potential hazards associated with the confined spaces that will be entered.

- Evaluation and control procedures for the identified or potential hazards.

- Set-up, use and limitations of all equipment such as emergency equipment, ventilation equipment (blowers), hazardous energy control, isolation and lockout equipment, and air quality monitors (e.g., Oxygen/combustible meters) that will be used while in the confined space.

- Set-up, use and limitations of all personal protective equipment (e.g., full-body harness, respirators) that the worker will be using while in the confined space.

- All safe work procedures for entering the confined space as outlined in the employer’s Confined Space Hazard Assessment Program.

- Procedures to follow in the event of a situation developing that could present additional risk to the worker or an emergency.

- The specific work to be done while in the confined space.

- To work in a manner that will not endanger lives.

Workers with emergency rescue responsibilities will need additional specialized training. All confined space training should include some hands-on training with the safety equipment including the PPE and safety harnesses. Rescue procedures should be practiced frequently so there is a high level of proficiency. Employers should keep records of all confined spaces training including refresher courses.

Dos and Don ts-Confined space:

- In a confined space emergency, the first thing you should do is report the situation immediately to the entry supervisor, who will notify the emergency rescue team.

- If the entrants can perform a self-rescue safely, keep in contact with them throughout the entire procedure, and assist them in any way possible without actually entering the space.

- If a non-entry rescue is required and you are trained, equipped, and authorized to perform a non-entry rescue, proceed with this procedure, keeping in constant contact with entrants.

- If the space must be entered to rescue entrants, keep in contact with entrants, if possible, let them know that help is on the way, and wait for the rescue team to arrive.

- Do not leave your post at the entry point to the confined space until the rescue team arrives.

- Do not allow anyone except the designated rescue team to enter a confined space in an emergency.

Click the below link to down load more details about confined space

confined-space-entry confined-space-work confined-space confined_space_permitClick the below link to know different confined space work permits formats

Confined Space Industrial Accidents and its investigation videos

Download above video click the below link

hazards-of-nitrogen-asphyxiation

Click below link for Investigation report

Click below link for Investigation report