Confined space rescue plan

Overview:

This lesson discusses procedures for confined space rescue operations and emphasizes the need for safe operating procedures . Practice and proficiency using mechanical- all will advantage systems, anchors, and rescue equipment is critical to the safety of all response personnel involved.

Objectives:![]()

- List the five priorities for emergency rescue operations.

- Explain the three types of confined space rescue.

- Identify specific rescue situations requiring special consideration.

- Explain anchor and rigging systems.

- Describe basic hand signals used during confined space rescue operations.

- Described basic rescue safety rules

Confined spaces can be deadly.

Many people are killed or seriously injured while working in confined spaces each year . According to the Workplace Safety and Health Council , 10 per cent of workplace fatalities were due to work-related accidents in confined spaces.

These fatal accidents happened across a wide range of industries: from complex plants to simple storage vessels. Those killed were not only people who worked in confined spaces but also others who tried to rescue them. Therefore good safety practices should be implemented to ensure a safe working environment for everyone.

Contributing factors to fatalities from confined space accidents:

- Absence of risk assessment prior to work commencement,

- Inadequate safe work procedures and emergency response plans;

- Absence of atmospheric testing prior to entry;

- Inadequate or absence of mechanical ventilation;

- Lack of proper supervision;

- Inadequate training;

- Lack of control of contractors and sub-contractors;

- Co-workers performing rescue without proper personal protective equipment and emergency

- response measures.

REMEMBER: An unplanned rescue will probably be your LAST.

It is “A MUST” to have a written and established rescue operation plan on-site that includes equipment, such as retrieval devices, breathing and resuscitating apparatus, ready for emergency use immediately. The severity of accidents can be reduced with timely alerts from attendants outside the confined space. A well-trained and fully equipped rescue team can ensure a speedy response in an emergency.

Emergency Rescue – The change in perspective:

Emergency rescue from a confined space is a matter of life and/or death. To this point we have concentrated upon routine entry and exit procedures. It may have appeared that we have not been making life and death decisions in these routine processes, but in fact, we have. When we routinely evaluate the space and perform the entry in accordance with the permit,weare making decisions that may mean the difference between a problem-freeentryand a body recovery. Many of these same thought processes that are required in the emergency rescue are also used in the routin entry. If that is the case,why is it so much more difficult to perform in an emergency setting? Lack of time is the critical factor. A sense of urgency is some times used as an excuse for making decisions or performing actions that place others at undue risk. Following are a few emergency rescue operation priorities.

The first priority is to keep all rescuers alive. It may seem callous, but you did not create this situation. It is your job to do everything that you and your fellow rescuers can SAFELY do to help the victim. However, there will be situations that you will not be able to help. It is critical that the person in charge of the rescue effort recognize when the risk to the rescuers sur passes the gain to the victim. When the risk is evaluated to be too great, it is imperative that the person in charge have sufficient character to delay or suspend the rescue effort even when that decision is unpopular.

Do not substitute emotion for intellect. In many cases, the people involved in the emergency will be under a great deal of emotional distress. This is especially true if the victim is a co-worker. Heightened emotion and a sense of urgency can also be a problem for the person in charge of the rescue. Bystanders and co-workers of the victim may exert great pressure to act on the person in charge. If the person in charge is not prepared for this, he/she may well get caught up in a flood of well- meaning but tactically incorrect thinking.

Don’t take shortcuts. As stated before, time is the enemy in rescue operations. Don’t allow rescuers to take shortcuts in appropriate procedures for the sake of saving time. This is especially true in space evaluation. If an emergency occurs in a space, a permit-like evaluation procedure needs to be performed unless the cause for the emergency can be unequivocally identified. Most of the time, short- cuts don’t save all that much time anyway. (Ever get lost taking a “shortcut“?) Rather than relying on shortcuts to shave time off of the response, practice, training, and preparation can maximize efficiency and enhance safety.

The person in charge may chose to isolate themselves. By being in a remote location, the person in charge can insulate himself/herself from the emotion of the rescue. Further more, this individual can choose with whom they will interact. There are no screaming bystanders or irate supervisors to deal with. Isolation may also improve access to communication facilities, technical information, or other resources that may prove helpful in the effort. Isolation is a matter of personal choice. If the person in charge chooses to be at the site of the rescue however, they should already have the mental mechanisms in place to deal with the distractions.

Preplanning and training:

The more your rescue team knows before the emergency, the safer and more efficient the rescue will be. Especially if you are an on-site rescue team, you should know the hazards that you will be faced with ahead of time. Equipment and personnel requirements should also have been determined in advance. Preplanning will help to identify the needed equipment and personnel. Training will turn equipment and personnel into a functional unit. While it is impossible to anticipate every situation, trained personnel with a well-rounded background in rescue principles will be able to address the emergency in as efficient a manner as possible.

Every person who is involved in a confinedspace rescue must not only have a mental image of the technical aspects of the rescue, but should also anticipate the entire range of emotional reactions that one would expect to encounter. Most people who deal in the emergency arena daily indicate that the keys to being a successful emergency worker are the ability to concentrate under pressure and the control of personal emotion. Once these hurdles arecrossed, one can think clearly and allow their training and experience to dictate their tactical objectives.

Confined Space Rescue:

Confined space emergencies are one of the leading causes of multiple deaths in the workplace. In most cases the emergency began with very few people in the space. Then untrained and/or unprotected “rescuers” added to the problem by entering the space and becoming victims them selves. As stated before, about 60 percent of victims are would-be rescuers. Additionally a majority of these individuals are supervisors and/or senior personnel who should know better. Oddly enough, there are many cases where the initial entrants survive and the would-be rescuers die.

The regulation mandates that an employer ensures the availability of rescue services prior to space entry. The rescue team may be from within the plant or may be from an outside agency. Either way, a specific mechanism needs to be in place prior to entry that guarantees that rescue resources are available if needed. Personnel assigned to an in-plant rescue team are to be provided with, and trained in the proper use of,the personal protective equipment necessary for making rescues from the employer’s permit spaces.

If the employer decides to use an in-plant team, the employer shall ensure that the in-plant rescue team is trained to perform the assigned rescue functions and has received the training required for authorized entrants. Rescue teams should practice making permit space rescues at least once every 12 months by means of simulated rescue operations. In these simulated rescue operations, they remove dummies, mannequins or personnel through representative openings and portals.

The size, configuration, and accessibility of these openings should closely approximate those of the permit spaces from which rescues may be required.

Each member of the rescue service shall be trained in basic first aid and cardiopulmonary resuscitation. At least one member of the rescue service holding current certification in basic first aid and cardiopulmonary resuscitation (CPR) shall be available during rescue activities. If the employer chooses to use outside rescue services, the employer shall inform the designated rescuers of the hazards they may confront when called to perform rescues the employer’s facility. While no specific permit is required for rescue, those involved in the rescue should review the entry permit and apprise themselves of the hazards they may encounter prior to entry. This is especially true for any outside services that may not be familiar with the particular space.

OSHA is aware that, from the viewpoint of elapsed time, in-plant rescue services are optimal. They also realize that not all employers have the equipment and/or the personnel for such a team. If an outside rescue service is used, their response time, their continuous availability during the entry, and their rescue capabilities need to be established prior to entry.

A specific mechanism for summoning the rescue service is required. In most cases specific phone numbers, radio frequencies, or other type of communication medium is listed on the entry permit. The attendant is responsible for that communication and should perform communications check prior to entry.

The employer shall provide access to all permit spaces from which rescue may be necessary so that the rescue service can develop rescue plans and practice operations. The employer shall also evaluate the response cabilities and training of the off-site response team.

Rescue Arrangements:

The risk assessment will determine what rescue arrangements are necessary. The arrangements will depend on the nature of the confined space, the risks identified and the types of emergency situations which are foreseeable. It is important to note the possible emergencies in the confined space, and any other foreseeable accident for a rescue operation. For example, the incapacitation of a person, wholly or partially, following a fall inside a confined space.

Possible confined space rescue strategies include the following:

- Self-rescue when the circumstances, the nature of the hazards and the control measures available allow;

- Rescue by team members (trained rescue personnel) using non-entry methods if feasible;

- Rescue by team members (trained rescue personnel) using a safe entry technique; and

- Rescue using a safe entry technique by the local public emergency services subject to adequate time being available (this depends on the nature of the hazards and the response time of the emergency services).

The risk assessment shall determine the combination of confined space rescue strategies appropriate for the particular situation.

It is important for suitable and sufficient emergency arrangements to take account of:

- Rescue considerations;

- Rescue logistics;

- Training of rescue personnel;

- Provision of rescue equipment; and

- Provision of safety data sheet.

Types of Rescue:

There are three types of rescue that may be employed in the confined space setting:

1. Self-rescue

2. Non-entry rescue – external

3. Entry rescue – internal

Self-rescue is when an entrant is capable of recognizing a hazard and is able to exit from the space with no assistance. Many times self-rescue involves the evacuation of a space when the entrant feels ill. In this situation the assumption is that a hazard within the space is causing the problem and that space evacuation is necessary until the problem is identified.

Obviously self-rescue has many advantages over the other two forms of rescue. With self-rescue, emergency rescue personnel do not have to enter the space. Risky extrication and/or removal techniques are not required if self-rescue can be employed. Also, by virtue of the fact that the individual is still conscious, the chances that the entrant will recover from the emergency are good. Hazard recognition can prevent serious exposure and injury.

The use of retrieval systems can be very effective in assisting in the rescue of an unconscious employee from a confined space. These systems allow rescue from outside the space. Here a problem may arise in that in order to provide the greatest degree of safety, the final rule requires the use of retrieval systems or methods whenever an authorized entrant enters a permit space except in situations in which retrieval equipment would increase the overall risk of entry or would not contribute to the rescue.

OSHA will use the following guidelines to make the determination for enforcement of this provision when inspecting permit spaces regarding retrieval systems:

1. A permit space with obstructions or turns that prevent pull on the retrieval line from being transmitted to the entrant does not require the use of a retrieval system.

2. A permit space from which an employee being rescued with the retrieval system would be injured because of forceful contact with projections in the space does not require the use of a retrieval system.

A permit space that was entered by an entrant using an air-supplied respirator does not require the use of a retrieval system if the retrieval line could not be controlled so as to prevent entanglement hazards with the air line.

However, exceptions from the use of a retrieval system from this standpoint may not necessarily exempt use of retrieval systems as described in 29 CFR 1910.134 (e)(3)(iii):

Persons using air line respirators in atmospheres immediately dangerous to life or health shall be equipped with safety harnesses and safety lines for lifting or removing persons from hazardous atmospheres, or other and equivalent provisions for the rescue of persons from hazardous atmospheres shall be used. A standby person or persons with suitable SCBAs shall be at the nearest fresh air base for emergency rescue.

Non-entry rescue, as the name implies, is rescue performed from outside the space. Prior to entry, retrieval systems and body harnesses should be in place in the event that conditions change. In most cases non-entry rescue involves removal using these lines. It’s important to plan and conduct the entry with this form of rescue in mind. Pulley systems, tripods, and space entryways should be arranged so that there is minimal chance for line entanglement. Non-entry rescue cannot be used for an individual who is entangled, trapped, or bound-up within the space; it can be used for engulfment situations as long as the amount of engulfing material is small enough to allow the victim to be unearthed using line tension. In some cases non-entry rescue is another name for body recovery. Individuals who are trapped in “no entry spaces,” or are in locations where the risk of entry far outweighs the gain, may have to be removed

Entry rescue is clearly the form of rescue that presents the greatest risk to the rescuer. It entails actually placing an individual into the hazardous space. Entry rescues should be avoided whenever possible. If entry rescue cannot be avoided, then SCBA, lifelines, harnesses, retrieval systems, and appropriate levels of protective clothing are required.

Planning and communication are vital in entry rescue. Since an entry is being made, all safety check protocols must be performed and an attendant will be required. If a change in the space is thought to have caused the emergency, appropriate testing and monitoring should be repeated. While a

Characteristics When Deciding the Appropriate Rescue Plan:

It is important to consider the following characteristics when deciding the appropriate rescue plan for a confined space entry work:

Internal Configuration:

i. Open — there are no obstacles, barriers, or obstructions within the space. One example is a water tank.

ii. Obstruction — the space contains some type of obstruction that a rescuer would need to manoeuvre. For example, a baffle or mixing blade. Large equipment, such as a ladder or scaffold, brought into the space for work purposes would be considered an obstruction if the positioning or size of the equipment would make rescue more difficult.

Elevation:

i. Elevated — a permit space where the entrance or opening is above ground by 4 feet or more.

This type of space usually requires knowledge of high angle rescue procedures because of the difficulty in packaging and transporting a victim to the ground from the space.

ii. Non-elevated — a permit space with the entrance located less than 4 feet above ground. This type of space will allow the rescue team to transport an injured worker normally.

Portal Size:

i. Restricted — A portal of 24 inches or less in the smallest dimension. Portals of this size are too small to allow a rescuer to simply enter the space while using SCBA. The portal size is also too small to allow normal spinal immobilisation of an injured worker.

ii. Unrestricted — A portal of greater than 24 inches in the smallest dimension. These portals allow relatively free movement into and out of the permit space.

Space Access:

i. Horizontal — The portal is located on the side of the permit space. Use of retrieval lines could be difficult.

ii. Vertical — The portal is located on the top or bottom of the permit space. Rescuers must climb down or up the permit space respectively to enter it. Vertical portals may require knowledge of rope techniques, or special patient packaging to safely retrieve a downed entrant.

For confined space entry, it is important for the authorised manager to designate a standby worker; one or more workers who are trained in industrial first aid, and also trained in confined space emergency and rescue procedures. It is necessary that the designated standby worker be present and remain at the entrance to the confined space at all times while his co-worker is in the confined space.

The authorised manager shall ensure that openings for entry and exit to a confined space are of adequate size to permit rescue of all persons who may enter a confined space. The openings are not obstructed by fittings or equipment which could impede rescue. It is important that rescuers be trained in and follow established emergency procedures and use appropriate equipment and techniques (such as lifelines, respiratory protection, and standby person).

Conducting of Drills:

It is important that all parties involved in a potential rescue operation understand and agree on the emergency and evacuation procedures. It is necessary to include all steps for safe rescue in the confined space entry procedures. It is also critical for a rescue to be well planned and evidence to be made available that indicates drills have been frequently conducted on emergency procedures. A rescue drill in a confined space shall be held at least once in every 12 months. The record of such a drill should be kept and should include the time, date of drill, personnel involved, a short description of the drill and the evaluation of the drill.

It is also important to note that workers who are not trained in proper rescue procedures should not undertake or be permitted to undertake rescue operations.

Specific Rescue Problems:

There are many confined spaces that would pose significant problems for rescue entry. Some of these rescues may be very complicated, thus pre-planning the rescue of each confined space on the premises will make the rescue procedure go smoothly, efficiently, and safely.

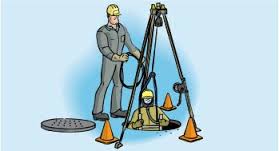

Vertical entry into tanks and vessels is relatively uncomplicated as long as a point of attachment can be made for a lifting device. Attachment to roof members, booms, or tripods on the tank make lifting easy.Tripods,however, are designed to lift from the center. A problem will be encountered if the patient needs to be lowered down the outside of the tank since the center of mass would now be outside the tripod. Another point of attachment or manual lowering will be necessary.

Dikes or vertical walls present a problem in that there is usually no point of attachment for a lifting device. A point of attachment can be made by raising an extension ladder above the wall, or by using a boom truck, forklift, or other elevated platform. If the extension ladder is used, make sure that the ladder is braced against lateral (side-to-side) movement.

Manholes are challenging because of their limited entrance areas. SCBA backpacks may have to be removed and passed though the hole to allow entrance. This is a very dangerous maneuver and should be attempted only by individuals specifically trained in this procedure. Finding a point of attachment for a lifting device may be a problem if a tripod is unavailable. This may be solved by placing two trucks side-by-side with the manhole in between. A ladder could then be placed across the trucks to span the space above the manhole. If this procedure is used, make sure the trucks are turned off and the vehicles isolated so that they do not move and their exhausts do not enter the space.

Atmospheres that contain corrosive chemicals are a threat to the nylon harness and rope material. In other atmospheres where skin exposure poses a threat to the rescuers, chemical protective clothing must be donned prior to entry. The application of a body harness and lifeline to someone in a fully-encapsulated suit has its challenges. The bulky nature of the suit will also impede and restrict movement in the space and in the space opening.

It is really important to determine the objectives of the rescue before making entry. It is imperative for the leader of the rescue group, as well as each rescue team member, to evaluate all potential hazards. The atmospheric conditions, entanglement and engulfment hazards, the circumstances of the accident, the time involved, and the probable victim outcome should all be given consideration prior to entry. Do not put the rescue team at undue risk to try to rescue a victim who may have already died.

Anchor and Rigging Systems:![]()

Anchor“ means to secure ropes and equipmentof the rescue system to something that is solid and will not fail under the stress of loading. Rigging is the system of rescue ropes and hardware attached to the anchor system. Anchors must be the strongest link within your system. “Bombproof” is a term for anchors strong enough to withstand any force the system may deliver to the anchor.

“Bombproof” Anchor Rigging:

A suspect anchor, or an anchor that may not be bomb proof, should be backed upwith a secondary anchor. However, the use of several weak anchor points is undesirable and should be avoided. If one anchor fails, the shock loading will lead to failure of all points. If a secondary anchor is needed, it should be as strong or stronger than the primary anchor.

Good structural anchors include structural steel, davit arms, beams, stairwells, and heavy hand rails. Bulk concrete anchors are found in supports, columns, and corner walls. Cast or insulated small diameter pipes, corroded metal, small diameter hand rails, old brickwork,light metal supports, and vents are not bomb- proof anchors and should be avoided. A tensionless tie-off utilizes the friction generated by coils of rope wrapped around the anchor as a means of anchoring a rope. A 4:1 tensionless anchor requires a minimum of three (3) wraps of rope around an anchor that is at least four (4) times the diameter of the rope. All other rigging must have a backup rig. If an anchor point has sharp edges, rigging should be padded.

Rigging Cautions:

- Do not run nylon over nylon rigging.

- Pad sharp edges as any bend under 4:1 weakens the rope (Spectra kevlar requires 8:1)

- Avoid hard linking, that is, three (3) or more carabiners linked together.

- Double check by sight and touch.

- Keep it simple.

- A pulley in rigging systems should always be backed up.

- Angles greater than 120° cause extra load on anchors.

Team Members and Their Duties:

A haul or lower team requires two to four people depending upon the mechanical advantage of the system. 4:1 systems require up to 4 people. Where as 5:1, or greater, systems require only two people. Within this team someone needs to be designated for the following duties:

- Person-in-charge or Incident Commander

- Belayer and Safety Line

- Hole watch/Attendant

- Cam-person

- Rescuer

Individuals may be required to cover more than one duty, such as, the Person-in- charge may also need to be the attendant or on the haul team. This is dependent upon the number of personnel available and the type of rescue/rigging system used.

As in any efficient operation, communication is important. Knowing what each individual is doing and their responsibilities is vital. Raising and lowering operations have specific verbal terms used and are said by specific personnel.

Rescue Safety Rules:

- Don’t proceed without proper PPE, equipment, personnel, and training.

- Make sure the confined space has been isolated.

- Use SCBA/SAR if not certain the atmosphere is safe.

- Do not use power equipment for human loads.

- Attendant never enters the space unless first relieved by another attendant.

- Have back-up rescue personnel available.

- Don’t risk a life for a body recovery. Weigh risk vs. benefit.

- Entry rescue team personnel requireme0n is about seven people.

Roles and Responsibilities of Supervisors, Entrants and Confined Space Attendants:

The main role of the supervisor is to provide direct and close supervision of the entry operations performed by the entrants and confined space attendants.

Supervisors are responsible for:

a. ensuring that entrants and confined space attendants are briefed on the safety and health precautions to take prior to confined space entry and work;

b. authorising entry into confined spaces;

c. ensuring that entrants and confined space attendants adhere to entry procedures;

d. rescue equipment and appointed rescue personnel are available when confined space work is to be carried out;

e. implementing control and preventive measures to manage all identified hazards are implemented;

f. applying the entry permit and have it endorsed by the Authorised Manager before commencement of confined space work;

g. terminating the entry permit after completion of work.

Entrants are responsible for:

a. following entry and work procedures when carrying out work in confined spaces;

b. carrying a portable gas/vapour measuring instrument for continuous monitoring of the atmosphere in the confined space for the full duration of their work;

c. inform the confined space attendant of any unsafe atmospheric conditions / when any emergency situation arise; and

d. inform co-workers to evacuate from the confined space should the portable gas/vapour instruments’ alarm be activated due to unsafe atmospheric conditions.

Confined space attendant is to:![]()

a. monitor entrants entering and working in a confined space;

b. maintain regular visual and or verbal contact with the entrants in the confined space;

c. inform entrants to evacuate the space should the need arise; and

d. alert the rescue personnel to activate the rescue operation in the event of an emergency.

Rescue Logistics:

It is important to give careful consideration on the means of raising the alarm and carrying out a rescue. This emergency plan needs to be suitable and sufficient for all anticipated accidents.

It is necessary to put in place measures that enable those in the confined space to communicate to others outside the space who can initiate rescue procedures or summon help in an emergency.

The emergency can be communicated in a number of ways, for example, by the tug of a rope, by radio or by means of a “lone worker” alarm. Whatever the system, it should be reliable and tested frequently. Depending on the risk assessment, it may be necessary to have one or more standby persons located outside the confined space whose function is to keep those inside in constant direct contact including visual where feasible, in case of an emergency.

It is also important to give careful consideration on the selection of an appropriate confined space rescue strategy. Retrieval using non-entry methods is preferable to rescue by entry and should be used where practicable.

Where entry is necessary, it is important to ensure the rescuers are protected from the risk of injury and to address any emergency situation.

Training of Rescue Personnel:

It is important for any person appointed to carry out any emergency arrangements to receive appropriate instruction and training to enable him to perform that role effectively. Such training includes first aid, CPR, the proper use of PPE and other equipment necessary for carrying out the rescue operation and as an authorised entrant. The level of training will vary according to the complexity and skill content of the role. It is necessary to conduct refresher training as often as possible to maintain an acceptable level of competence.

Familiarity with procedures and equipment is essential. It can be developed and fine-tuned by frequent drills and realistic simulation.

All rescue personnel need to understand the likely causes of an emergency. They will need to be familiar with the rescue plan and procedures developed for each type of confined space that they may encounter. They need to be able to rapidly size-up an emergency situation and evaluate their ability to conduct a safe rescue. These factors need to be given consideration in the development of a training programme. It is important to design the training in such a way that rescuers are capable to perform rescues in a safe and timely manner.

Rescuers need to be fully familiar with the equipment for use in rescue, communications or medical purposes and operation. They would need to check that the equipment is functioning well before use. It is important for potential users of breathing apparatus to receive appropriate formal training. It is critical for trained persons to carry out the resuscitation procedures efficiently. Designated first-aiders need appropriate current certification.

Provision of Rescue Equipment:

Suitable and sufficient rescue equipment is needed to respond to an emergency in a timely and safe manner. It is important to list the appropriate equipment for the likely type of emergencies in the risk assessment. It is crucial to maintain the rescue equipment properly and make them readily available whenever and wherever confined space work is undertaken.

For example, rescue equipment may include:

- Full body harness with retrieval line attached;

- Hand-cranked mechanical winch and tripod (required when entrant is five feet or more below the entrance);

- Ladder;

- Explosion-proof lighting;

- Breathing apparatus;

- Stretcher;

- Approved head protection; and

- Resuscitating apparatus.

Rescue equipment will often include SCBA. Its duration in use is governed by the size and number of cylinders and its type (open- or close-circuit).

Personal Protective Equipment (PPE):![]()

It is essential to conduct a proper assessment of conditions and identify work processes that require additional protective equipment for the task to be undertaken. For example, the possibility of personal exposure to toxic substances and traumatic injury requires the consideration of full body protection.

It is necessary to provide appropriate first aid equipment and make available for emergencies. It is important to have first-aiders trained to deal with the foreseeable injuries.

It is essential to maintain and inspect all equipment provided for an emergency. Inspection also includes periodic examinations and tests according to the manufacturer’s instructions or the appropriate requirements of health and safety legislation.

The examination of ropes, harnesses, lifelines, protective clothing, and other special equipment will normally consist of a thorough visual examination of all their parts for deterioration or damage, in particular, on those parts that are load-bearing. It is necessary for the examinations to be carried out regularly and a record kept of them.

Click the below link to download the PPT and safety check sheet

Confined space rescue drill

Confined space rescue